Home

About us

News

Products

Lease

Service

Order

Contact us

CH/EN

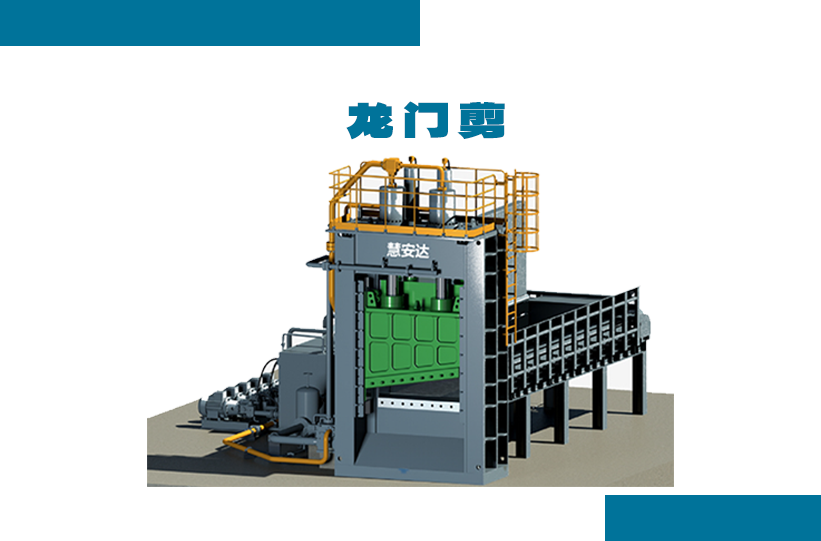

This SERIES OF products ARE SUITABLE FOR COLD CUTTING PROCESSING OF various scrap metal profiles and structural parts in small and medium-sized metal recycling stations, furnace charge processing in foundry, and can also be combined with large GANtry shears to cut the material twice after a cut, which is the most ideal choice to replace the traditional crocodile shears.

Product Features:

1. Chain plate bin is adopted to realize continuous feeding in the working process, reduce the waiting time of equipment and increase output;

2. Siemens/Mitsubishi control system is adopted to automate the shearing process. Only one person is required to operate the equipment.

High work efficiency, compared with crocodile scissors, high safety, and greatly reduce labor intensity and labor cost;

3. friendly widescreen human-computer interaction interface, visual shear process monitoring, easy to operate and learn;

4. the use of automatic lubrication system, lubrication process self-monitoring;

5. the machine has the characteristics of low energy consumption, small footprint, flexible and convenient use.